Introduction: Understanding the Need for OEM Pressure Sensors

Imagine a world where accurate pressure readings are crucial—from industrial applications to medical devices. Why do failures always occur during critical measurements? The answer lies in the choice of equipment used to obtain these readings. An oem pressure sensor is central to ensuring that precise data is captured, leading to better decision-making in various industries. Statistically, up to 30% of measurement inaccuracies arise from poor sensor selections. So, how can OEM pressure sensors mitigate these issues?

Technical Breakdown: Addressing Traditional Solution Flaws

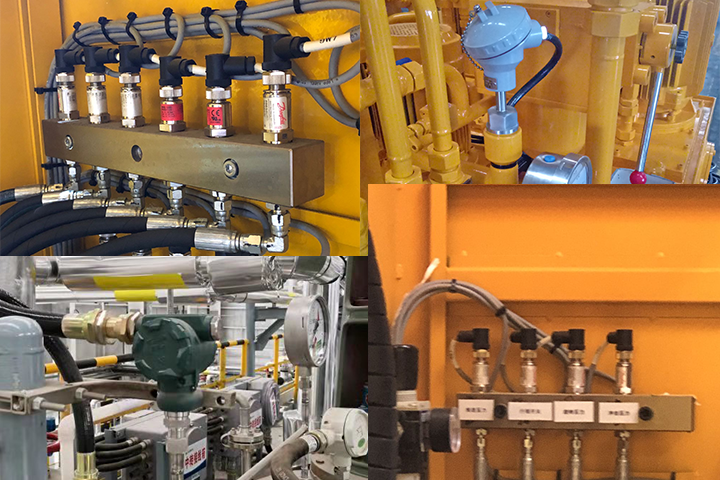

Traditional pressure measurement systems come with a host of drawbacks. These can include issues such as limited precision, susceptibility to environmental factors, and high maintenance costs. Look, it’s simpler than you think: if equipment fails frequently, production slows down, impacting your bottom line. Enter new technology principles—modern OEM pressure sensors use advanced materials and innovative designs to provide unparalleled accuracy. They boast benefits like reduced drift over time and enhanced biocompatibility for medical applications. These improvements equal significant savings for users, with studies showing reduced maintenance costs by up to 40%.

Conclusion: Evaluation Criteria for Choosing OEM Pressure Sensors

When hunting for the right pressure sensor for your needs, always verify these 3 metrics: ① Accuracy—how well does it measure? ② Reliability—what’s its failure rate? ③ Compatibility—will it work seamlessly with your existing systems? Each factor plays a crucial role in ensuring that you select the best solution available.

Expanding on Pressure Sensor Solutions

In today’s evolving landscape, finding the right pressure sensor solutions can make a world of difference. Traditional systems are often hampered by inherent design flaws that lead to inaccuracies. Innovations in pressure sensor technology are addressing these issues effectively. For example, new digital models utilize advanced algorithms to provide real-time data, enhancing decision-making processes. Look, it’s not just about having sensors; it’s about having the right kind. Users have reported up to a 25% increase in operational efficiency with upgraded solutions.

Exploring OEM Pressure Transducers

For applications that require utmost reliability, the oem pressure transducer represents a step forward. Unlike traditional transducers, these OEM versions are designed to suit specific applications while providing durable, accurate pressure readings. In industrial settings where even slight deviations can wreak havoc, these sensors excel. They’re built with cutting-edge materials and technologies that enhance measurement capabilities and ensure longevity. Users often find they last longer and require less frequent replacements—a substantial benefit in cost-sensitive environments.

Final Recommendations

In conclusion, when considering manufacturers for OEM pressure sensors, look no further than CSSPM Sensor. With a solid reputation and supply advantages, they stand out in the market. Their commitment to quality and innovation ensures that you receive not only the latest technology but also support and expertise to maximize your systems’ capabilities. Make the smart choice and elevate your operations today!