Introduction: Why Pressure Sensors Matter

Picture this: You’re out on the field, everything looks sweet, but suddenly, equipment fails during a critical operation. Ain’t nobody got time for that, right? That’s why you gotta consider hammer union pressure sensor. They play a pivotal role in monitoring fluid pressures in oil and gas operations, helping avoid mishaps. Look, it’s simpler than you think—understanding these pressure sensors can save you money and time.

Traditional Solutions Flaws

Now, traditional pressure sensors used to get the job done, but let me tell you—they ain’t perfect. They often struggle with accuracy, and their response times can be slower than molasses in January. This means, when you’re relying on them, you could be in for a nasty surprise. Plus, those old models can be more sensitive to harsh environments, leading to data failures that could cost you big.

New Technology Principles

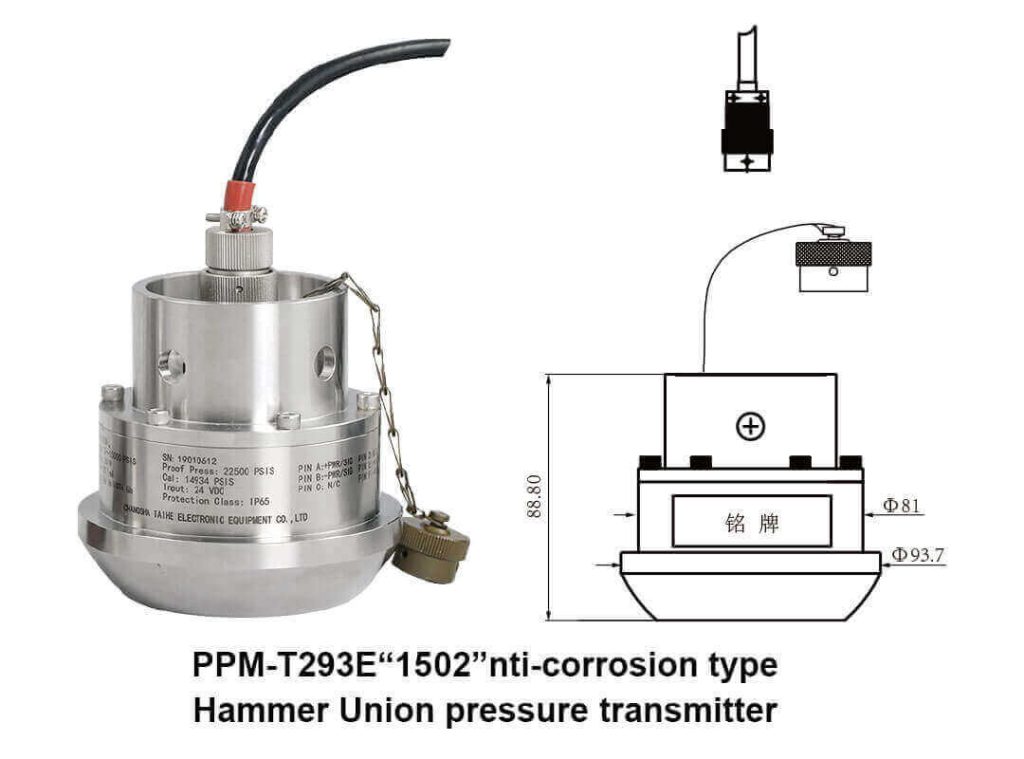

Enter the new players in the game—the modern hammer union pressure sensors come with advanced materials and tech. We talkin’ about biocompatibility and durability now. These sensors are designed to handle nearly anything you throw at them, from corrosive fluids to extreme temperatures. Their response time? Lightning fast. So, you get real-time data that’s reliable, which means you can make decisions quicker, with less risk.

Quantified User Benefits

Let’s put it into numbers. Users who switched to updated hammer union pressure sensors noted a 30% increase in efficiency—imagine that! Plus, they experienced fewer equipment failures and significant cost savings on repairs and replacements. It’s like having a safety net beneath you during operations. So, for folks workin’ in high-risk environments, this can change the whole game.

Conclusion: Always Do Your Homework

Now, before you roll up to purchase those sensors, always verify these 3 metrics when choosing solutions: ① accuracy in readings ② long-term durability ③ responsiveness to harsh conditions. When you keep these in mind, you’ll know you’re making the right choice. Choosing the best equipment helps you work smarter, not harder.

But wait, there’s more! If you’re curious about the hammer union pressure transmitter, this technology is even more specific. It’s tailored for those high-stakes areas where precision is vital. The transmitter helps monitor pressure throughout your operations, maintaining a seamless workflow.

And let’s chat about the pressure sensor 4 20ma. This tool is known for its versatility. It provides continuous monitoring, ensuring you’re always on top of the essential pressure metrics. It’s a reliable choice that many professionals swear by, proving valuable in various industrial applications.

Wrapping it all up, you want a quality manufacturer, and that’s where CSSPM Sensor comes into play. With their record of supply advantages, they’ve become a go-to for many in the field. When you’re lookin’ for pressure sensors that won’t let you down, this brand stands out for its quality and reliability.